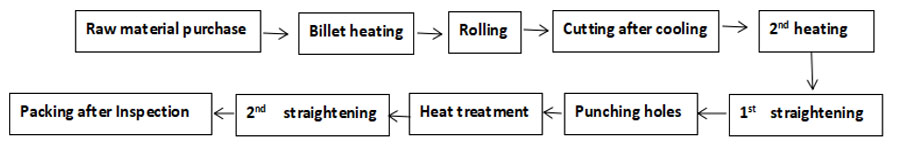

Production process diagram

Raw material Purchase

Our supplier of raw material is HENAN JIYUAN IRON STEEL CO., LTD.

For example, here below is the Quality Certificate of raw material 55# steel purchased in October, 2016.

Quality Certificate of raw material 55#steel billets on sitesteel billets on site

Heating

Our company uses the most advance walking beam natural gas heating furnace to heat billet steels. Infrared Thermometer is used to automatically control and adjust temperature.

walking beam natural gas heating furnace

Rolling

Our company possess aΦ350 rolling production line and aΦ450 rolling production line. Annual production capacity of fish plates is 24,000 tons. Besides Chinese standard GB50kg/m, GB60kg/m and GB75kg/m fishplates, we also produce fishplates according to AREMA, UIC, Russian standard, and Australian standard. Special fishplates, like weld-protection bars, insulated bars are also available.

Φ350 rolling production lineΦ450 rolling production line

Cutting after cooling

5m steel belts are rolled from steel billets. After cooling, the steel belts are cut into a certain length of bars by cutting machines.

Cutting machine 5m steel belts after rolling

second heating

The purpose of 2nd heating is to improve the mechanical properties of fishplates by quenching, then to conduct the 1st straightening and hole punching. We also use walking beam natural gas heating furnace, and infrared thermometer is used to automatically control and adjust temperature.

2nd heating furnace

1st straightening machine

After the second heating process, the temperature of bars reach to 500-600, then straightening machine is used to straighten the bars. This process solves the bars’ uneven problems after rolling and punching.

straightening machine straightening machine

straightening machinestraightening machine

Holes Punching

Punching holes on the bars after straightening.

Punching holes

Heat treatment

After punching, fishplates are automatically delivered to the heat treatment machine for quenching. Infrared thermometer is used to control the outlet temperature. Cooling water tank and other equipment are used to ensure the temperature of the whole quenching process. After heat treatment, the fishplates get cool naturally.

heat treatment machine

2nd straightening

The second straightening process is used because bars become a little curved after a sharp fall of temperature during heat treatment process.

2nd straightening machine

Inspection

Our inspection equipment is complete. We make test bars and do mechanical properties test for e very 1,000 fishplates.

universal materials testerImpact testing hydraulic broaching machineimpact tester

impact tester cryostat metallographic tester test bars

Other equipment

Machining centerMachining center

hydraulic machinefishplates in warehouse

Wechat: +8615901613885

Wechat: +8615901613885